Polyolefin elastomers (POE) are revolutionizing industries from automotive to solar power with their superior performance and versatility. As a leading material in photovoltaic applications, POE is setting new standards in replacing traditional rubber and plastics, enhancing both durability and sustainability.

Guide Overview

This guide provides an insightful overview of POE, covering its essential properties, uses in solar panels, and advantages over materials like EVA and EPE. Key sections include:

- What are Polyolefin Elastomers?

- Properties and Applications

- POE vs. EVA and EPE

- Future Trends

Explore how POE is transforming material science and advancing solar technology.

What is Polyolefin Elastomers( POE)?

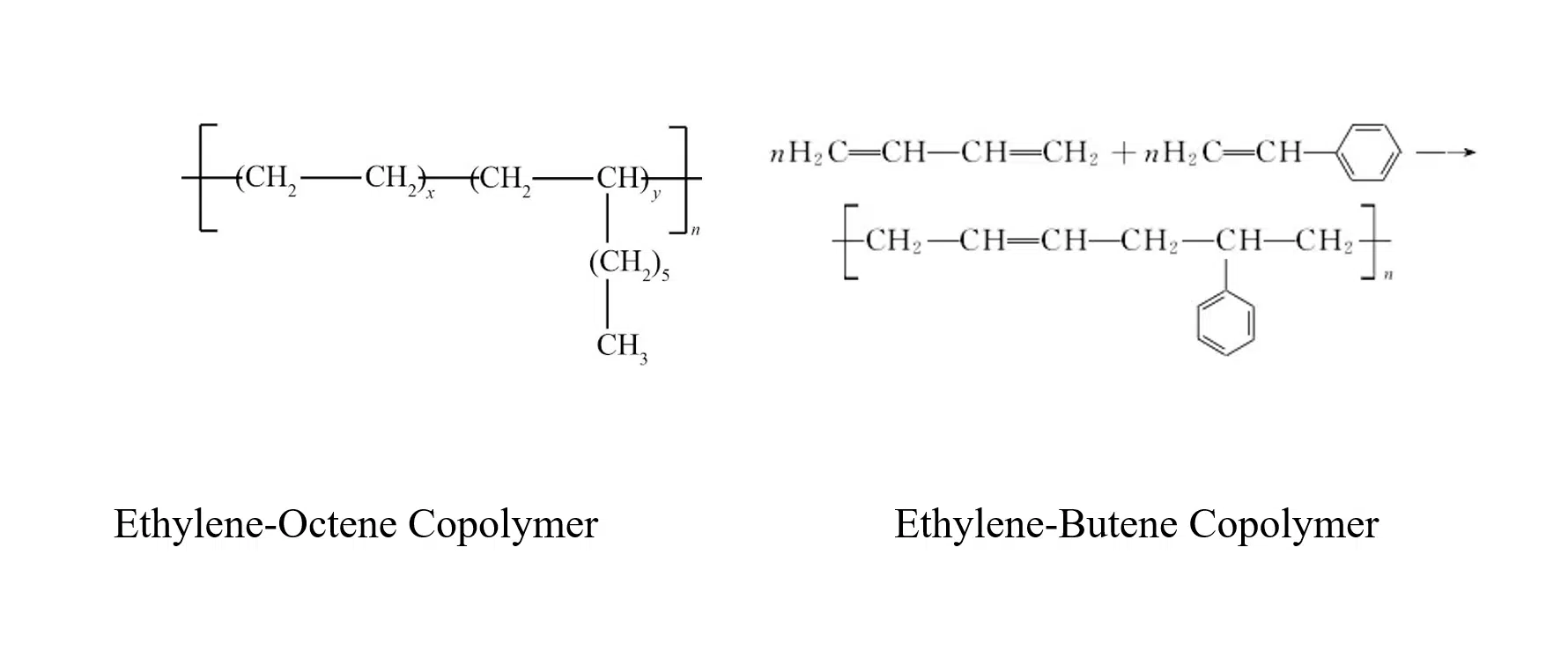

Polyolefin elastomer (POE material) is a high-performance material from the copolymerization of ethylene and alpha-olefin. Compared to other common plastics such as Low-Density Polyethylene (LDPE), it exhibits excellent elasticity, toughness, and temperature resistance, which are crucial for enhancing the durability and efficiency of products that include POE. These characteristics make POE an ideal choice for applications in the manufacture of high-grade POE/PVC POE products.

POE does not release harmful gases when burned, which makes it environmentally friendly. Moreover, the low density and high elastic recovery of POE improve the overall performance of products incorporating this material.

Polyolefin Elastomers (POE) Material Characteristics

The basic characteristics of POE elastomers are high octene mass fraction (greater than 20%), low density, very narrow relative molecular weight, a certain degree of crystallinity, its structure of crystalline PE exists in the side chain of the amorphous copolymer monomer, the crystalline PE chain links as a physical cross-linking to withstand the load, and non-crystalline ethylene and octene long chain to provide elasticity. Its specific properties are as follows:

- Outstanding low-temperature impact resistance

- Low specific gravity and cleanliness

- Outstanding heat sealability

- Excellent compatibility with various base polymers

- Excellent flexibility and puncture resistance

- Very high inorganic filler properties

- Excellent elongation and high elasticity

- Good light transmission

- Excellent electrical insulation properties

Polyolefin Elastomers (POE)Application in Solar Panels

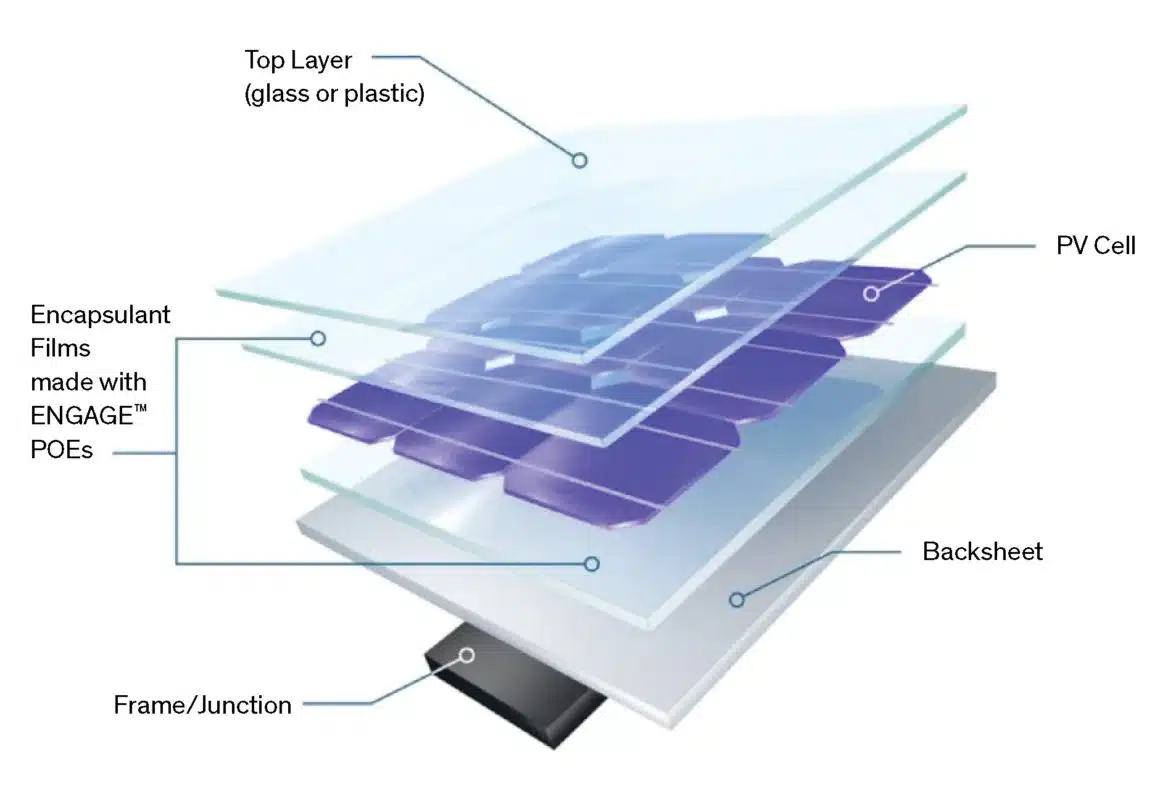

POE material is one of the core auxiliary materials of solar panels, mainly used for encapsulation film, in addition to common photovoltaic encapsulation materials such as EVA film, EPE film in the cost of the component accounted for about 4-6%, although not high, its service life of the component, photoelectric conversion efficiency is very obvious.

The PV module structure from bottom to top is glass, encapsulation film, battery sheet, encapsulation film, and back sheet/glass, the photovoltaic adhesive film will be the battery sheet with the top cover below the pad sealing method, and the main role is to protect the solar cell sheet, so that photovoltaic modules in the operation of the process of the external environment, to extend the service life of photovoltaic modules.

Many professional solar panel manufacturers have already put POE materials into the solar panel manufacturing process. Sungold’s application of POE materials in the encapsulation of bifacial solar panels effectively extends the life and overall efficiency of the group leader.

At the same time, to maximize the sunlight through the film to reach the surface of the battery sheet, to improve the power generation efficiency of photovoltaic modules. Therefore, photovoltaic encapsulation film is required to have the pros:

- high transmittance

- UV resistance

- weather resistance

- moisture barrier

- good electrical characteristics

POE Vs. EVA Material: Properties Comparison

Compared with EVA film, POE film has a higher water vapor barrier rate, weather resistance, and stronger anti-PID performance.

Its water vapor transmission rate is only 1/8 of that of EVA film, which can effectively reduce the PID effect, and it is mainly used for the encapsulation of monocrystalline PERC (emitter and back-side passivated cell) bifacial solar panels and N-type solar cell modules.

POE vs. EVA

| Performance Indicator | EVA | POE |

|---|---|---|

| Density | 0.96 g/cm³ | 0.88 g/cm³ |

| Polarity | Polar | Non-polar |

| Acidity/Alkalinity | Acidic | Neutral |

| WVTR (38°C, 90%RH) | 20-40 g/m²/day | 2-5 g/m²/day |

| UV Stability | Weak | Strong |

| Crosslinking Rate | Fast | Slow |

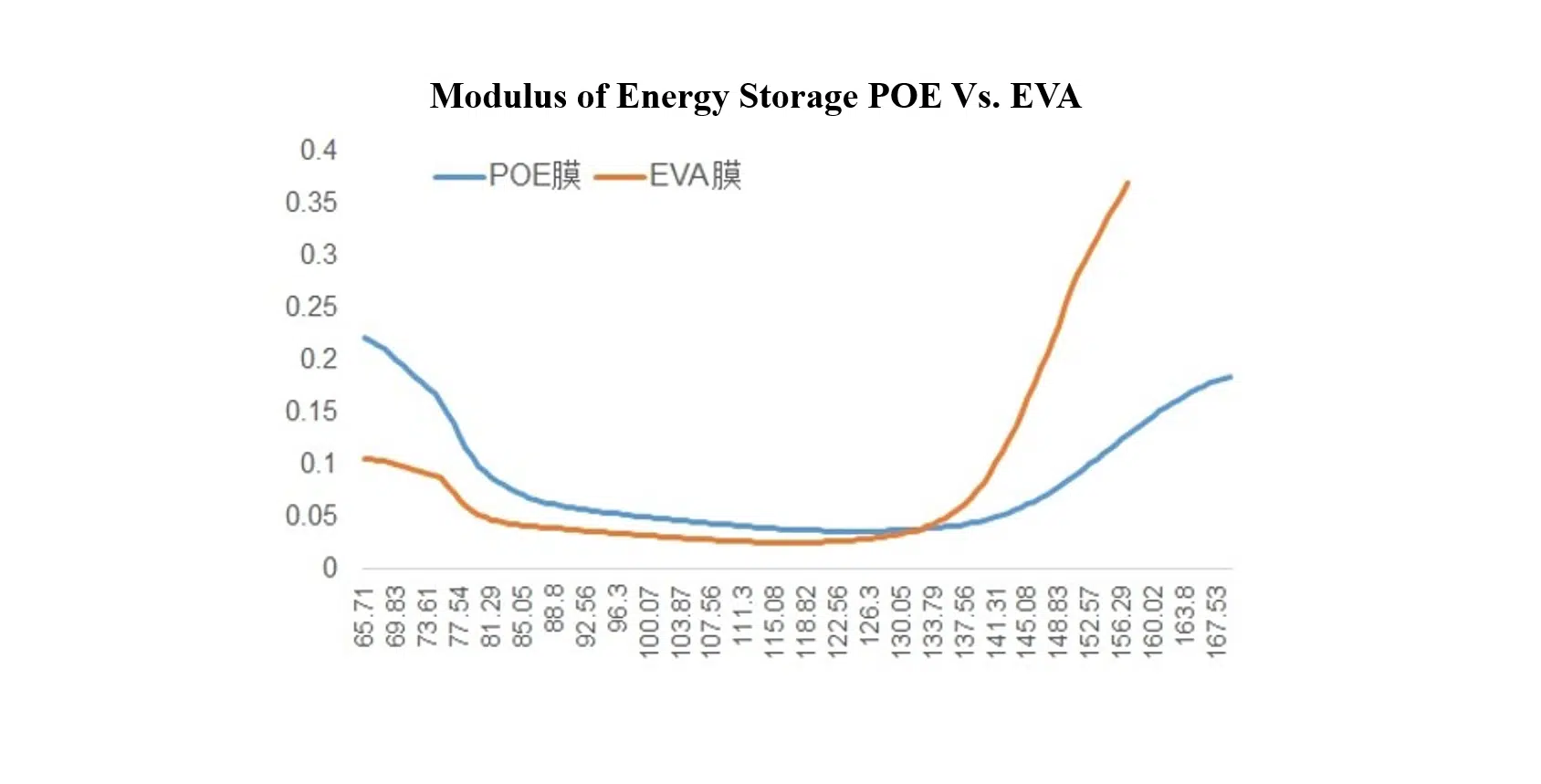

Graph showing :

- The change in modulus of uncross-linked EVA and POE as the temperature increases.

- When cross-linking is complete, the modulus of EVA is generally higher than that of POE.

- Higher modulus films put more stress on thin wafer cells

Compared to EVA films, POE films are superior :

Volume resistivity

Volume resistivity is one of the key electrical performance indicators of the film, usually the higher the volume resistivity, the more effective the material used as an electrical insulating component. At high temperatures, the volume resistivity of Polyolefin Elastomers (POE) is 1-2 orders of magnitude higher than that of ordinary EVA film. POE film can more effectively reduce the occurrence of PID phenomenon in the module and improve the safety and reliability of the module.

Water vapor transmission rate

POE belongs to non-polar materials, can not form hydrogen bonds with water molecules with excellent water vapor barrier, circumventing the weakness of EVA film adsorption of water vapor, water vapor transmission rate of one-tenth of the EVA material, which can effectively prolong the use of the module cycle and reduce power degradation.

UV aging performance

EVA film with the extension of the aging time, its yellowness index gradually climbed, while POE film due to the saturated structure of the macromolecular chain, the molecular structure contains relatively few tertiary carbon atoms, with more excellent aging resistance and UV resistance.

POE vs. EPE Material Performance Differences

We will discuss the performance differences between two different encapsulation materials, POE and EPE materials.

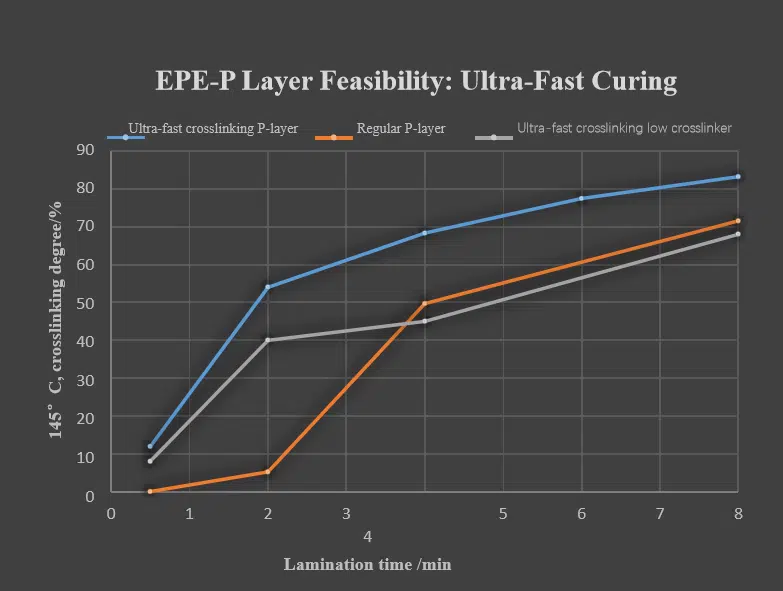

EPE film is a three-layer composite film with an “EVA-POE-EVA” structure.

It is a co-extruded POE film that combines the high water resistance and anti-PID performance of POE film with the lamination characteristics of EVA film used in double-glass components.

This film is ideal for encapsulating PV modules, such as PERC double-face dual glass and N-type double-face double-glass, that demand high weather resistance.

Stability

- EPE: additives are easy to migrate to EVA, and EPE performance will change with longer storage time.

- POE: additives are easy to migrate to the surface.

Low-temperature performance

- EPE: internal stress increases, and solar panels perform poorly at low temperatures under snow load.

- POE: meet the outdoor demand, better performance of solar panels.

Thickness controlling

- EPE: uneven

- POE: no thickness control problem, more stable PID performance.

Uniformity of crosslinking degree

- EPE: EVA is higher than POE

- POE: no uniformity problem

Performance difference

- EPE: quality risk

- POE: A low cross-linking degree of POE will produce empty glue, bubbles, aging delamination, and other problems.

N-Type Cells Drive POE Demand Growth

At present, the photovoltaic industry is dominated by P-type batteries. Still, the conversion efficiency of P-type batteries is close to the limit, the future as N-type battery technology breakthroughs and yield enhancement, is expected to take over the P-type battery as the next generation of mainstream technology.

N-type solar cells put forward higher requirements for the encapsulation film: N-type batteries with a silver paste containing aluminum, the film requires higher water-blocking properties, and N-type batteries PN junction and P-type batteries on the contrary, the front side is more likely to produce PID phenomenon. POE does not contain acetate, which ensures that it has no acid decomposition in hot and humid environments, so it can meet the needs of N-type batteries for anti-PID, acid resistance, water vapor resistance, and so on.

The feasibility of EPE for TOPCon solar cell encapsulation is great. EPE products should first solve the problem of poor cross-linking of the POE layer, especially the problem of reduced cross-linking of additives after migrating from the POE layer to the EVA layer.

POE Material Development Directions

Stage 1 (Light Blue Circle):

Transition: 8C to 4C

Description: Enhance the stability of 4C POE performance.

Stage 2 (Dark Blue Circle):

Transition: Miscibility to Integrated Machine

Description: Optimize performance improvement through enhanced miscibility.

Stage 3 (Green Circle):

Transition: Toroidal Light Transformation

Description: Improve light transformation efficiency.

Stage 4 (Light Blue Circle):

Transition: Lower Temperature Environmental Impact

Description: Reduce environmental impact.

Stage 5 (Yellow Circle):

Transition: Anti-Crosslinking and High Crosslinking

Description: Enhance crosslinking functionality, simplify the process.

Environmental Impact and Sustainability

Environmental considerations are crucial in the adoption of new materials. POE’s production involves fewer toxic emissions compared to traditional materials, and its potential for recycling presents opportunities for reducing waste in solar panel manufacturing.

Regulatory and Standards Compliance

Adhering to international standards such as ISO and ASTM, POE materials meet stringent requirements for safety, performance, and environmental impact, facilitating their adoption across global markets.

Conclusion

As the solar industry evolves, the role of materials like polyolefin elastomers in advancing solar technology becomes increasingly significant. Their superior properties, coupled with ongoing advancements and favorable market dynamics, position POE as a key player in the future of photovoltaic applications.

- More details about N-type and P-type solar energy cells can be found in our previous article: History of Photovoltaic Cells from P-Type to N-Type Solar Panels

- More details about TOPCon solar cell can be found in our previous article: What Is A TOPCon Solar Cell?

- More information about Solar Panel Manufacturing Process: Reliable Solar Module Manufacturers: Exploring the Shingled Solar Panel Manufacturing Process