What is ETFE in solar panels? ETFE is a fluoropolymer thermoplastic material that is widely used in various industries. ETFE material’s full name is Ethylene Tetrafluoroethylene.

In this article, we will delve into the properties, applications, and benefits of ETFE material.

ETFE Material Properties

ETFE is a lightweight material with high tensile strength and excellent resistance to impact, weather, and chemicals. It is also highly transparent, allowing for up to 95% of natural light transmission, and has a low surface energy, which makes it self-cleaning and resistant to staining.

ETFE also has a wide temperature range, with the ETFE melting point around 267°C, and a maximum service temperature of 150°C. It is also highly durable, with a lifespan of up to 50 years, and can be recycled at the end of its useful life.

- Lightweight: ETFE is a lightweight material.

- High Tensile Strength: It has a high tensile strength, providing structural stability.

- Excellent Resistance: ETFE is resistant to impact, weather, and chemicals.

- High Transparency: Allows up to 95% of natural light transmission.

- Low Surface Energy: Self-cleaning and resistant to staining.

- Wide Temperature Range: Melting point around 267°C, with a maximum service temperature of 150°C.

- Highly Durable: Has a lifespan of up to 50 years.

- Recyclable: Can be recycled at the end of its useful life.

Applications of ETFE Material

ETFE’s unique properties make it suitable for a wide range of applications, including:

Architectural roofing and cladding: ETFE creates lightweight and energy-efficient building envelopes, such as the Eden Project in the UK and the Beijing National Aquatics Center in China.

Agriculture: ETFE can be used as a covering material for greenhouses, allowing for maximum light transmission and crop growth.

Aerospace: ETFE is used in aircraft components, such as wiring and insulation, due to its lightweight and durable properties.

Electrical and electronics: ETFE can be used as insulation for wiring and cables, as well as in the manufacturing of printed circuit boards and semiconductors.

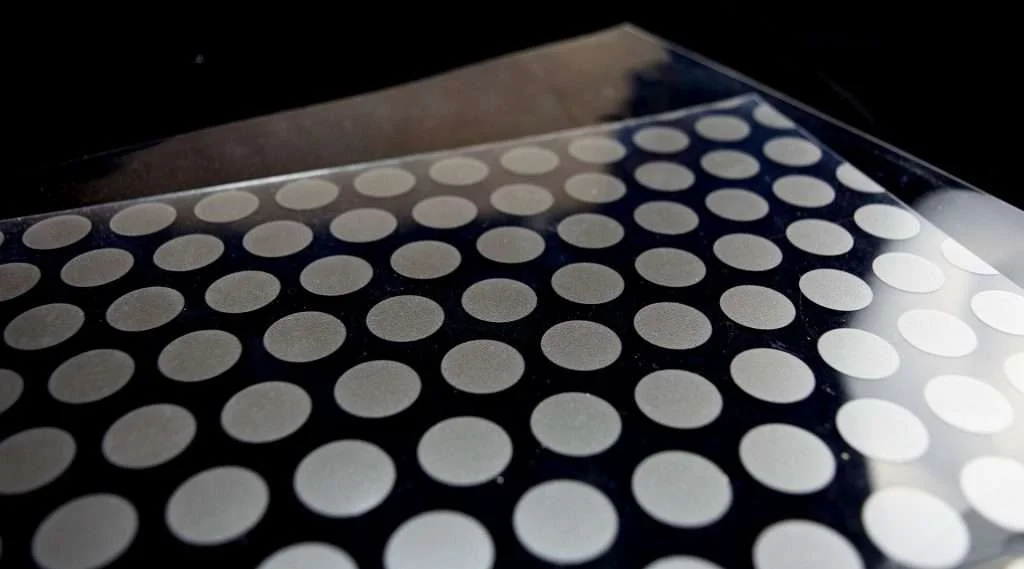

PV modules: ETFE material is often used as a surface material in the manufacture of some photovoltaic modules to make ETFE solar panels, which usually have stronger sunlight absorption and better waterproof performance.

Are ETFE solar panels any good?

ETFE offers several benefits, including:

Energy efficiency: ETFE’s high transparency allows for maximum natural light transmission, reducing the need for artificial lighting and lowering energy consumption.

Durability: ETFE’s high resistance to impact, weather, and chemicals, as well as its long lifespan, make it a cost-effective and low-maintenance material.

Sustainability: ETFE can be recycled at the end of its useful life, reducing waste and contributing to a more sustainable future.

Design flexibility: ETFE can be fabricated into a variety of shapes and sizes, allowing for greater design flexibility and creativity.

What is the difference between PET and ETFE?

Both ETFE (ethylene tetrafluoroethylene) and PET (polyethylene terephthalate) are materials that can be used in the construction of solar panels, but they have different characteristics and advantages. Let’s explore the differences between the two:

Material Properties

ETFE (Ethylene Tetrafluoroethylene): ETFE is a fluorine-based polymer known for its high light transmittance and exceptional durability. It’s highly resistant to UV radiation, weathering, and chemicals, making it a suitable choice for outdoor applications like solar panels.

ETFE panels tend to have a longer lifespan and can maintain their transparency and efficiency over time.

PET (Polyethylene Terephthalate): PET is a common plastic polymer used in various applications, including packaging materials and textiles. While PET panels might be less expensive, they typically have lower light transmittance compared to ETFE. PET panels are generally not as durable as ETFE panels and can degrade more quickly when exposed to harsh weather conditions and UV radiation.

Transparency and Efficiency

ETFE: ETFE has a higher transparency to visible light and ultraviolet (UV) light compared to PET. This means that ETFE panels allow more sunlight to pass through to the solar cells, potentially leading to higher energy generation and efficiency.

PET: PET panels may have slightly lower light transmittance, which can result in slightly reduced energy generation compared to ETFE panels.

Durability

ETFE: ETFE panels are known for their exceptional durability. They can withstand extreme temperature variations, high winds, hail, and other environmental stressors without significantly degrading. This durability often leads to a longer lifespan for solar panels constructed with ETFE.

PET: PET panels are generally less durable than ETFE panels. They are more susceptible to UV degradation and may become discolored or brittle over time, especially when exposed to harsh sunlight and weather conditions.

Cost

ETFE: ETFE panels are typically more expensive to produce due to their advanced properties and durability. However, their longer lifespan and potential for higher energy generation can make them cost-effective in the long run.

PET: PET panels are generally less expensive to produce, which can make them an attractive option for certain applications where cost is a significant factor.

| Aspect | ETFE Solar Panels | PET Solar Panels |

|---|---|---|

| Material Properties | High light transmittance | Lower light transmittance |

| Exceptional durability | Less durable | |

| UV, weather, and chemical resistant | Prone to UV degradation | |

| Transparency | Higher transparency to visible and UV light | Slightly lower light transmittance |

| Efficiency | Potential for higher energy generation | Slightly reduced energy generation |

| Durability | Excellent resistance to harsh conditions | Less resistant to environmental stress |

| Lifespan | Longer lifespan | Shorter lifespan |

| Cost | More expensive to produce | Less expensive to produce |

Conclusion

Many photovoltaic modules use ETFE materials to improve module efficiency, such as flexible solar panels and portable solar panels which use ETFE as a surface material to improve module efficiency and have been tested with very positive results.

ETFE is a versatile and durable material with a wide range of applications and benefits. Its unique properties make it an excellent choice for a variety of industries, from architecture to aerospace. As the demand for sustainable and energy-efficient materials increases, ETFE is sure to continue to play a key role in shaping the future of modern technology and design.

FAQ

Can you walk on ETFE solar panels?

Yes, Sungold introduces ETFE solar panels TF-S SERIES that are flexible enough to support an adult’s footsteps, making them ideal for installation on yachts or fishing boats where it’s difficult to avoid stepping on them.

How durable is an ETFE solar panel?& What is the lifespan of ETFE solar panels?

The service life of ETFE solar panels varies, the service life of flexible solar panels can reach 15~20 years, portable solar panels have long and short service life because of the differences in appearance and design, which can be categorized into 3~5 years and 5~15 years.

Ethylene tetrafluoroethylene (ETFE) is a fluorine-based polymer, and it is made from the polymerization of ethylene and tetrafluoroethylene monomers. This synthetic polymer belongs to the class of fluoropolymers, which are known for their excellent chemical and thermal resistance.

The production of ETFE typically involves the copolymerization of ethylene and tetrafluoroethylene in the presence of a catalyst. This process results in a polymer with a unique combination of properties, including high strength, transparency, flexibility, and resistance to harsh environmental conditions.

ETFE is commonly used as a construction material for architectural purposes, such as in the form of films for roofing and facades. It is also utilized in various industrial applications due to its remarkable chemical and electrical properties. Additionally, ETFE is known for its lightweight nature, which makes it a popular choice for applications where weight is a critical factor.